PRODUCTS

-

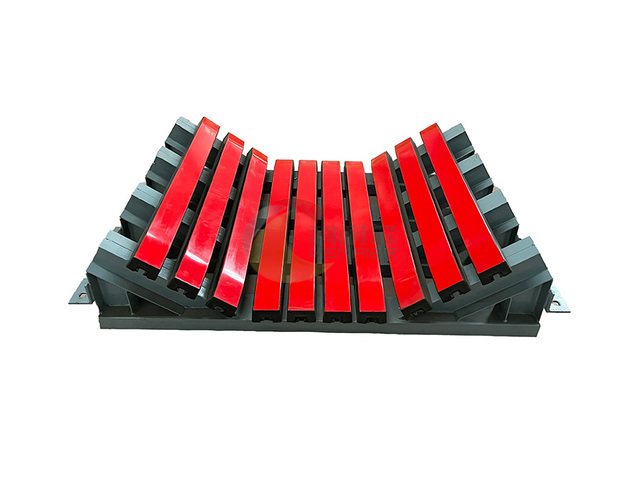

Impact bed

The buffer bed is mainly used to replace the buffer roller. The buffer bed is composed of buffer strips, and the buffer strips are mainly made of excellent high-elasticity special rubber layer to fully and effectively absorb the impact force of the falling material, greatly reduce the impact of the falling material on the conveyor belt, and truly improve the stress condition of the falling point.

-

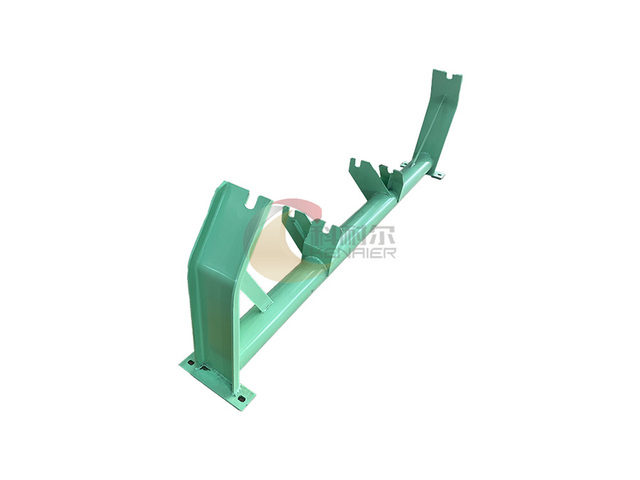

Hydraulic correction bracket

The hydraulic deviation correction bracket supports the hydraulic deviation correction device, and is composed of a self-aligning wheel composite pump composed of a self-aligning wheel and an oil pump, a combined oil cylinder composed of an integrated block and an oil cylinder, and an oil pipe mechanism.

-

Slot bracket

The trough-shaped bracket is mainly suitable for the brackets on TD75 and DTⅡ. The main brackets include trough-shaped brackets, parallel brackets, self-aligning brackets, V-shaped brackets, etc.! The trough-shaped bracket is widely used.

-

Self-aligning bracket

The trough-shaped bracket is mainly suitable for the brackets on TD75 and DTⅡ. The main brackets include trough-shaped brackets, parallel brackets, self-aligning brackets, V-shaped brackets, etc.! The trough-shaped bracket is widely used.

-

Tapered roller

The tapered rollers are divided into tapered upper centering rollers and tapered lower centering roller groups. The tapered rollers are wear-resistant and have a long service life.

-

Ceramic roller

Ceramic rollers are composite components consisting of a ceramic body, bearings, shafts, and plastic labyrinth seals. They are a new breakthrough in the application of replacing steel and plastic with porcelain through high-temperature calcination. They are a new generation of roller replacement products. They are composite components consisting of a ceramic body, bearings, shafts, and plastic labyrinth seals.

-

Friction roller

Friction rollers have a strong ability to prevent conveyor belt damage and deviation. They use the friction resistance and the deviation mechanism of the friction wheel arc to prevent and correct the conveyor belt from deviation and achieve the effect of self-aligning.

-

Spiral roller

Spiral rollers are mainly used to clean up debris adhering to the belt and can also play a certain role in adjusting the deviation. The structure is that a spiral round steel with a diameter of 10 to 14 mm is welded on the ordinary roller or a spiral groove cast rubber sleeve is added to the outer surface to increase the wear resistance of the entire roller, which can thoroughly clean up the adhesion on the belt and effectively ensure the service life of the belt conveyor belt.

-

Polyurethane roller

Polyurethane rollers are constructed from polyurethane elastomers, combining the high toughness of plastics with the elasticity of vulcanized rubber. They offer damping and cushioning functions, making them suitable replacements for vulcanized rubber and steel springs in die-casting mold processing industries.