PRODUCTS

-

Conveyor belt

Rubber, fiber, metal composite products, or plastic and fabric composite products used in belt conveyors to carry and transport materials. Conveyor belts are widely used in cement, coking, metallurgy, chemical industry, steel and other industries where the conveying distance is short and the conveying volume is small.

-

Hydraulic Self-Aligning Idlers

Hydraulic self-aligning idlers are advanced components used in conveyor systems to maintain precise belt alignment and reduce wear on the conveyor belt. These idlers utilize hydraulic pressure to automatically adjust their position, ensuring that the belt remains centered and aligned throughout its operation. This feature is particularly beneficial in environments where conveyor belts are subjected to varying loads, angles, or conditions that can cause misalignment.

-

conveyer carrying idler

The conveyor carrying idler bracket is a critical component in conveyor systems, designed to support and secure carrying idlers. These brackets are essential for maintaining the proper alignment and tension of the conveyor belt, ensuring smooth and efficient material transport. Constructed from durable materials, they provide stability and reliability in various industrial applications such as mining, cement plants, and bulk material handling facilities.

-

DT 75 conveyor

The DT 75 conveyor is a robust and versatile conveying solution widely used in industries such as mining, metallurgy, coal, and cement. It features a durable structure designed to handle various bulk materials over both short and long distances. The conveyor operates using a continuous belt supported by rollers, ensuring smooth and efficient material transport. Its design allows for horizontal, inclined, and vertical conveying applications, making it suitable for diverse industrial settings.

-

DIT II conveyor

The DT II type belt conveyor is a robust and versatile conveying solution widely used in industries such as mining, metallurgy, coal, and cement. It features a durable structure designed to handle various bulk materials over both short and long distances. The conveyor operates using a continuous belt supported by rollers, ensuring smooth and efficient material transport. Its design allows for horizontal, inclined, and vertical conveying applications, making it suitable for diverse industrial settings.

-

Pipe belt conveyor

A pipe belt conveyor, also known as a tube conveyor or tubular conveyor, is a type of conveyor belt that encloses the material being transported within a tube-shaped casing. This design helps to prevent material spillage and dust emissions, making it particularly suitable for transporting materials that are sensitive to environmental factors or require protection from contamination.

-

DJ DJII high angle edge conveyor

The DJ and DJII high angle edge conveyors are designed for efficiently transporting materials at steep angles, such as ores, coal, and slag. They prevent material slippage and accumulation, enhancing conveying efficiency in industries like mining, construction materials, and ports.

-

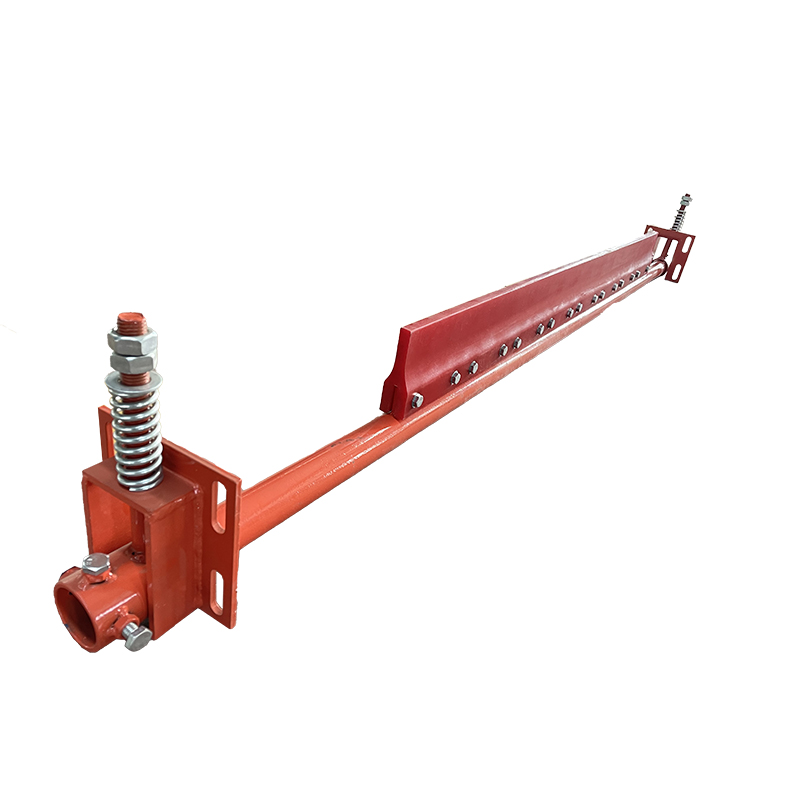

Conveyor Belt Cleaner P-Type Belt Cleaner

The P-Type Secondary Belt Cleaner represents an advanced solution in conveyor belt cleaning technology, engineered to deliver superior performance, durability, and efficiency in managing residual material on conveyor systems. This innovative cleaner combines robust design with high-quality materials to ensure optimal conveyor belt operation across diverse industrial applications.

-

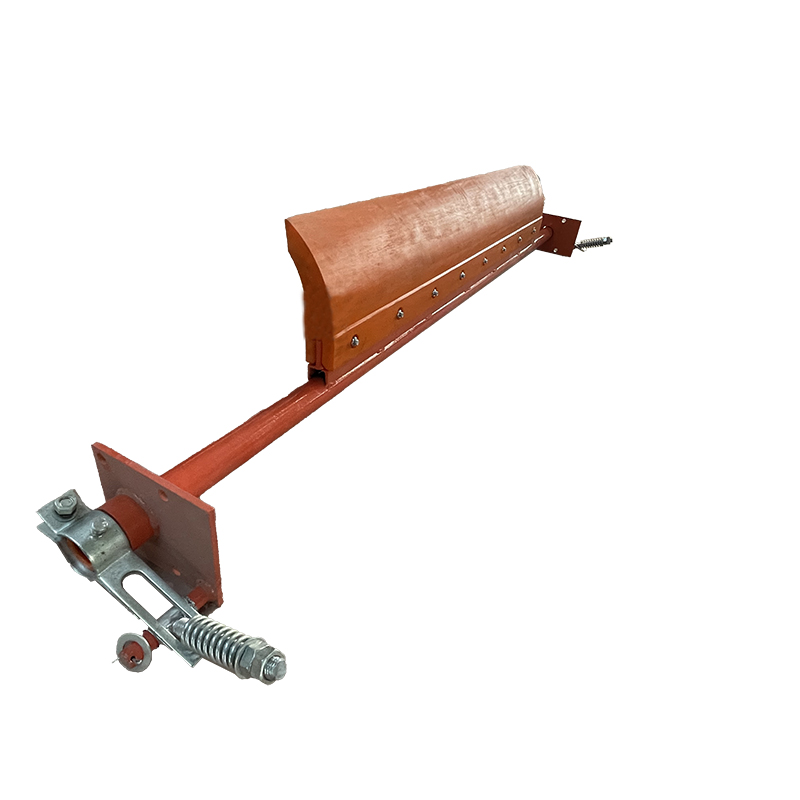

H-Type Primary Belt Cleaner

The H-Type Primary Belt Cleaner sets a new standard in conveyor belt cleaning technology, designed to deliver exceptional performance, durability, and efficiency in managing material carryback on conveyor systems. This innovative solution combines robust construction with advanced materials to ensure optimal conveyor belt operation across various industrial applications.