PRODUCTS

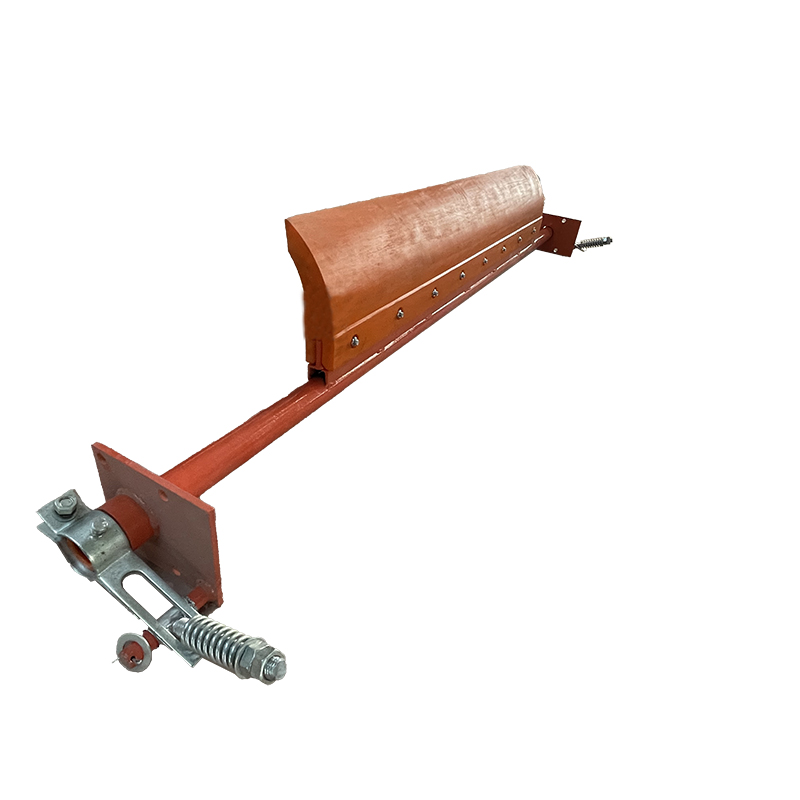

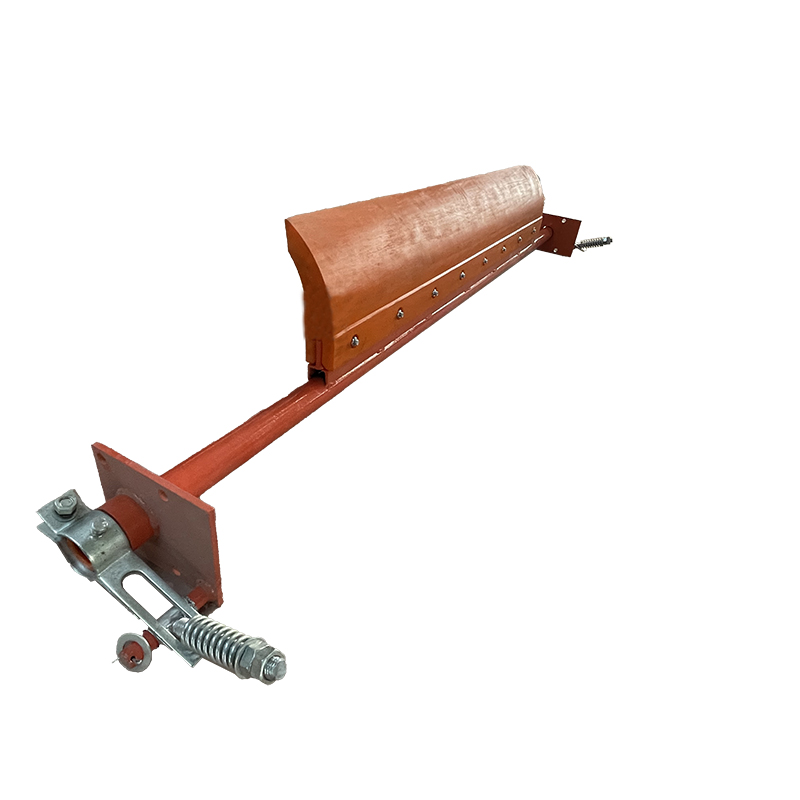

H-Type Primary Belt Cleaner

Product Struction

Product Introduction: H-Type Primary Belt Cleaner

The H-Type Primary Belt Cleaner sets a new standard in conveyor belt cleaning technology, designed to deliver exceptional performance, durability, and efficiency in managing material carryback on conveyor systems. This innovative solution combines robust construction with advanced materials to ensure optimal conveyor belt operation across various industrial applications.

Key Features and Benefits:

- Efficient Material Removal: Featuring a robust H-shaped blade design, the cleaner effectively removes bulk material, fines, and carryback from the conveyor belt's surface, preventing spillage and reducing cleanup time.

- Adaptable to Various Belt Conditions: Suitable for use on both vulcanized and mechanically spliced conveyor belts, the H-Type Cleaner adapts seamlessly to different belt widths and speeds, maintaining consistent cleaning effectiveness.

- Durable Construction: Constructed from high-quality polyurethane or tungsten carbide materials, the cleaner blade is resistant to wear and abrasion, ensuring long-term durability and minimal maintenance requirements.

- Adjustable Mounting System: Equipped with an adjustable mounting system, the cleaner maintains optimal blade-to-belt contact pressure, maximizing cleaning efficiency while minimizing belt wear and tear.

- Simple Installation and Maintenance: Designed for straightforward installation and quick blade replacement, the H-Type Cleaner reduces downtime and enhances operational continuity with minimal effort.

- Enhanced Safety Features: Incorporating safety guards and ergonomic components, the cleaner promotes a safe working environment for maintenance personnel, mitigating risks associated with manual cleaning methods.

- Environmental Compliance: Engineered to minimize material loss and airborne dust emissions, the cleaner supports environmental sustainability efforts, contributing to cleaner and safer work environments.

- Cost-Effective Solution: By reducing carryback and spillage, the H-Type Primary Belt Cleaner optimizes conveyor system efficiency, lowers operational costs, and improves overall productivity over the long term.

Applications:

Ideal for industries such as mining, aggregates, cement production, and bulk material handling, the H-Type Primary Belt Cleaner offers essential maintenance support for conveyor systems. It effectively manages material carryback on both standard and specialty conveyor belts, ensuring continuous operation and maximizing conveyor belt lifespan.

Conclusion:

The H-Type Primary Belt Cleaner exemplifies cutting-edge innovation and reliability in conveyor belt cleaning technology, offering unmatched performance and durability. Whether for new installations or retrofitting existing conveyor systems, its robust design, versatile application, and cost-effective benefits make it an indispensable component in industrial operations. Discover how the H-Type Primary Belt Cleaner can enhance your conveyor belt performance and streamline material handling processes with efficiency and precision.