PRODUCTS

-

Belt Steel Spiral Idlers

Belt Steel Spiral Idlers are essential components designed for belt conveyors, specifically engineered to enhance the efficiency and reliability of material transport in various industrial applications. These idlers play a crucial role in supporting and guiding conveyor belts, ensuring smooth and continuous operation under demanding conditions.

-

Buffer Roller Idler for Belt Conveyor

Cushioning impact rollers are essential components designed for belt conveyors, specifically engineered to absorb and reduce the impact of conveyed materials on the conveyor belt. They play a crucial role in enhancing the operational efficiency and longevity of conveyor systems by mitigating damage and minimizing downtime due to material impact.

-

Polymer Rollers Belt Conveyor Idlers

High molecular polymer rollers are essential components designed for belt conveyors. They play a crucial role in supporting and guiding conveyor belts, reducing frictional losses during operation, and protecting the conveyor belt itself. These rollers are crafted from high molecular polymer materials known for their exceptional wear resistance and corrosion resistance, ensuring long-term durability and stable performance.

-

conveyor Normal roller

The roller shaft is made of high-precision cold-drawn steel, and the pipe material is a high-frequency seam welded pipe with uniform wall thickness, high roundness, straightness and precision, which effectively reduces radial runout and ensures uniform rotation during operation.

-

Brush cleaner

The rotating brush cleaner is located under the return conveyor belt of the conveyor, which can effectively clean the adhesion on the roller surface and the bottom of the conveyor belt.

-

Air cleaner

-

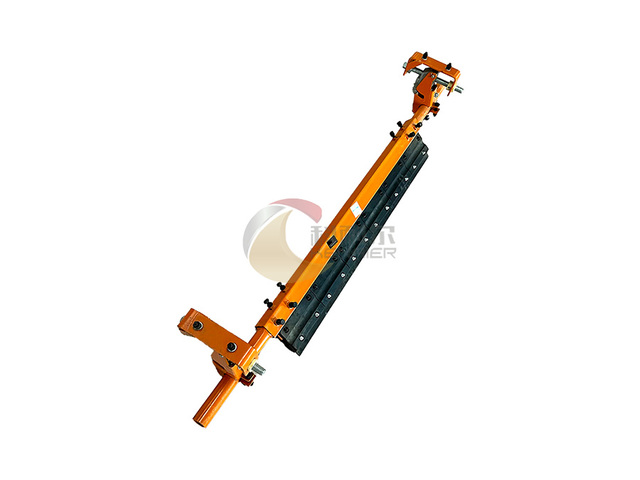

German Martin sweeper

This cleaner adopts a spring structure, which can automatically adjust the blade, so that the blade plate maintains the best adhesion with the tape surface, cleans the tape adhesion, and eliminates the disadvantage of the alloy blade plate that is easy to damage the tape. Good elasticity, this cleaner uses the spring length adjustment device to automatically adjust the cleaning plate.

-

P-type cleaner

The P-type cleaner is installed on a stable working surface near the head wheel. It is used to remove the adhered materials near the bottom of the head wheel.

-

H-type cleaner

The H-type cleaner is installed near the head wheel, near the tangent point that is 15 degrees to the horizontal line of the head wheel center. It is used to remove adhered materials near the top of the head wheel.