PRODUCTS

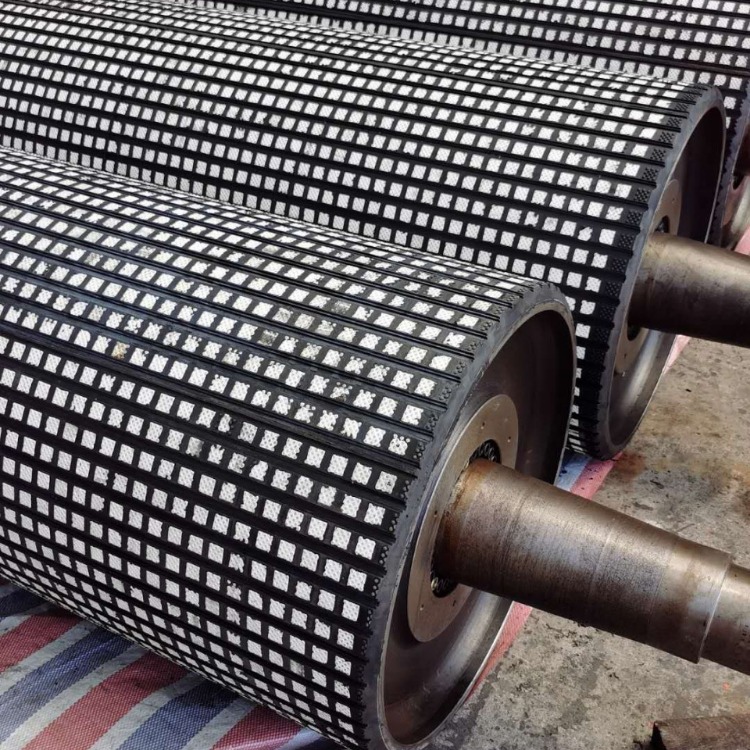

Abrasion-resistant Ceramic Lagging Pulley Lagging

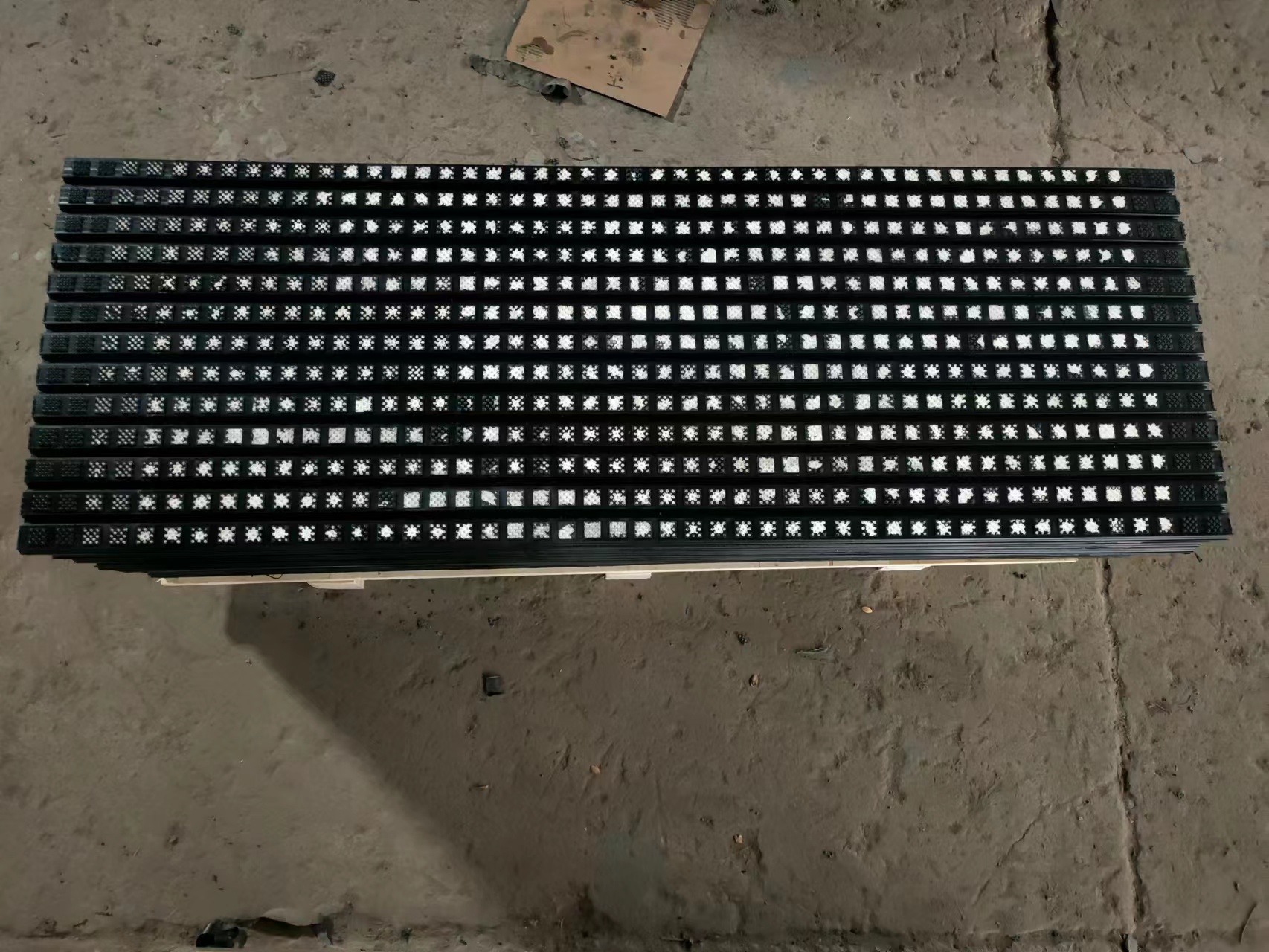

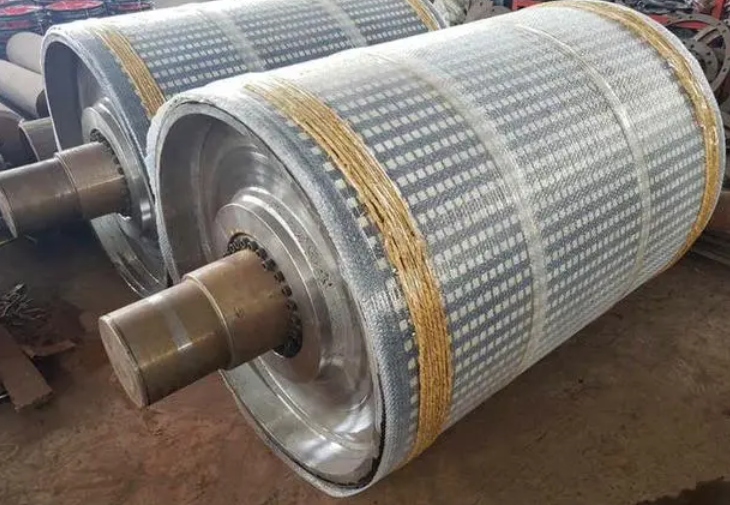

Product Struction

Product Introduction: Abrasion-Resistant Ceramic Lagging Pulley Lagging

The Abrasion-Resistant Ceramic Lagging Pulley Lagging represents a pinnacle in conveyor system technology, engineered to deliver unmatched durability, performance, and reliability across a wide array of industrial applications. Crafted with meticulous attention to detail and utilizing cutting-edge materials, this coating ensures optimal conveyor belt performance under the most demanding operational conditions.

Key Features and Benefits:

- High-Density Ceramic Tiles: Embedded within a durable rubber matrix, high-density ceramic tiles provide superior wear resistance and exceptional grip, effectively reducing belt slippage and enhancing traction in high-torque applications.

- Abrasion Resistance: The ceramic lagging coating offers exceptional resistance to abrasion, impact, and corrosion, extending the service life of conveyor belts and pulley systems in industries such as mining, cement production, and aggregate handling.

- Enhanced Material Flow: Designed with a smooth surface and precision-engineered ceramic tiles, the coating minimizes material buildup and reduces friction, ensuring smooth material flow and enhancing operational efficiency.

- Robust Construction: Manufactured from high-strength materials such as natural rubber and premium ceramic tiles, the coating withstands heavy loads and harsh environmental conditions, maintaining optimal performance even in extreme temperatures and abrasive environments.

- Customizable Design: Available in various thicknesses and configurations, the ceramic lagging Pulley Lagging can be customized to meet specific conveyor system requirements, accommodating different pulley diameters and belt speeds with ease.

- Environmental Sustainability: Engineered for energy efficiency and reduced noise emissions, the coating supports sustainable practices without compromising operational effectiveness, contributing to a greener industrial environment.

- Safety and Compliance: Incorporating safety features such as non-slip surfaces and optional emergency braking systems, the coating enhances workplace safety and complies with industry regulations and standards.

- Versatile Applications: Ideal for a wide range of applications including bulk material handling, recycling, and heavy-duty conveying tasks, the ceramic lagging Pulley Lagging optimizes conveyor system performance with reliability and longevity.

Conclusion:

The Abrasion-Resistant Ceramic Lagging Pulley Lagging sets a new standard in conveyor system technology, offering unparalleled durability, performance, and adaptability. With its advanced ceramic tile technology, robust construction, and customizable options, this coating ensures efficient material handling operations while minimizing maintenance costs and downtime. Whether for new installations or retrofitting existing systems, this coating exemplifies excellence in industrial conveyor solutions.