PRODUCTS

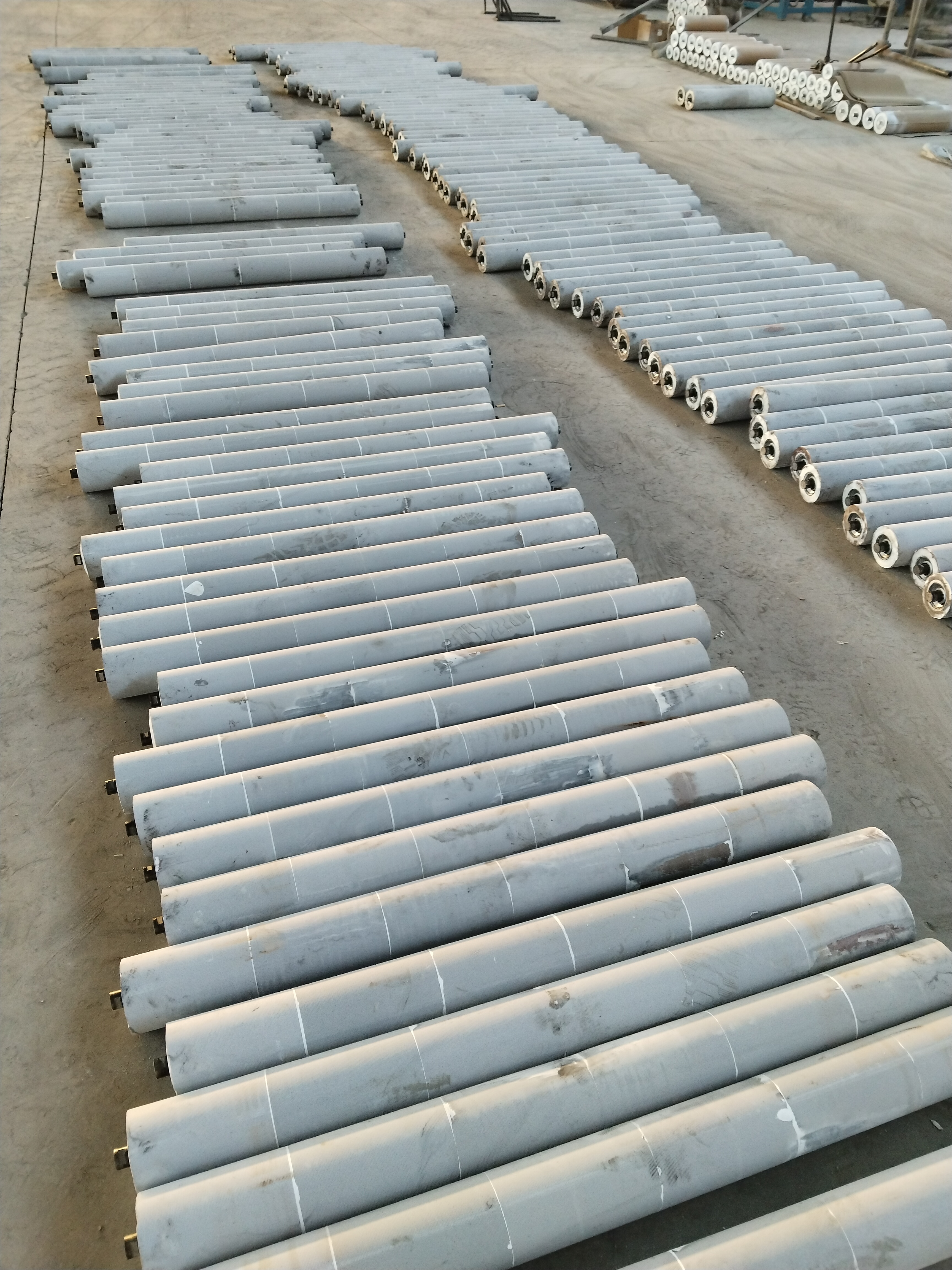

Ceramic Belt Conveyor Roller

Product Struction

Product Introduction:

Ceramic Belt Conveyor Rollers are advanced components designed for enhancing the performance and longevity of belt conveyors in industrial applications. These rollers integrate ceramic materials known for their exceptional hardness, wear resistance, and thermal properties, making them ideal for demanding environments where conventional rollers may struggle to maintain efficiency.

Key Features and Advantages:

- High Wear Resistance: Constructed from high-grade ceramic materials such as alumina or silicon nitride, ceramic rollers offer superior wear resistance compared to traditional steel or rubber rollers. This extends the operational life of the roller and reduces maintenance frequency.

- Temperature Stability: Ceramic materials exhibit excellent resistance to high temperatures, making ceramic rollers suitable for applications where conveyed materials or ambient conditions involve elevated temperatures or thermal variations.

- Corrosion Resistance: Ceramic rollers are inherently resistant to corrosion and chemical degradation, ensuring reliability in environments where exposure to corrosive substances or moisture is a concern.

- Reduced Friction: The smooth surface and hardness of ceramic materials reduce friction between the roller and conveyor belt, improving operational efficiency and minimizing energy consumption.

- Material Contamination Prevention: Ceramic rollers help prevent contamination of conveyed materials, as they do not generate debris or particulates that could affect product quality in sensitive industries like food processing or pharmaceuticals.

- Application Versatility: Suitable for a wide range of industries including mining, steel production, cement manufacturing, and bulk material handling, where reliable conveyor performance and durability are critical.

- Enhanced Safety: By maintaining stable conveyor operation and reducing wear on the conveyor belt, ceramic rollers contribute to a safer working environment with fewer maintenance-related risks.

Ceramic Belt Conveyor Rollers represent a cutting-edge solution for industries seeking to optimize conveyor performance with durable, high-performance components that withstand challenging operational conditions.