PRODUCTS

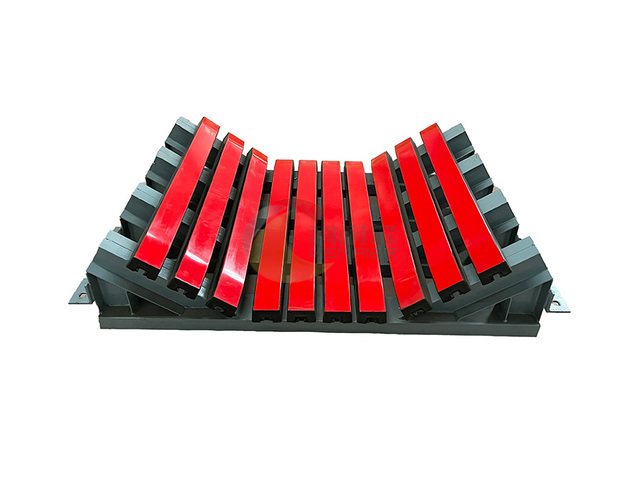

Impact bed

Product Struction

The buffer bed is mainly used to replace the buffer roller. The buffer bed is composed of buffer strips, and the buffer strips mainly use excellent high-elastic special rubber layers to fully and effectively absorb the impact of the falling materials, greatly reducing the impact of the falling materials on the conveyor belt, and truly improving the stress condition of the drop point. And the special UHMW polymer polyethylene surface is used to minimize the friction coefficient between the conveyor belt and the buffer strip, and it has good wear resistance. The use of the buffer bed ensures the surface-to-surface contact of the conveyor belt, and the force is evenly distributed, which effectively prevents the longitudinal tearing of the belt caused by the breakage and falling of the rollers, and greatly reduces the probability of the belt being longitudinally torn after being penetrated by sharp objects or sharp materials.

Advantages of use

1. The surface contact between the buffer strip and the conveyor belt effectively prevents damage to the conveyor belt

2. The conveyor belt is evenly stressed at the drop port, greatly reducing the cost of daily repairs and maintenance

3. Effectively eliminate material splashing and leakage caused by uneven stress on the conveyor belt

4. The smooth surface of the ultra-high molecular weight polyethylene minimizes the friction of the conveyor belt during operation

5. The arc design of the polyethylene layer surface ensures the smooth operation of the conveyor belt

6. The ultra-high elastic special rubber layer can absorb the impact of materials to the maximum extent

7. The various parts of the buffer strip are connected by hot vulcanization process, which is compact and firm

8. The design of the bottom steel structure makes disassembly and assembly convenient and fast

The advantages of the buffer bed in all aspects determine that it must be the development trend after the traditional roller support.

Recommended application occasions

1. High drop point buffer. 2. Uneven drop buffer. 3. High-density drop buffer. 4. Improved sealing of the drop area (to prevent overflow). The buffer bed is an alternative to buffer rollers. It can absorb impacts, prevent belt tearing, slow down the impact and damage of materials on the tape, avoid tearing and scratching of the tape by sharp objects, and is the best solution to prevent material overflow and spilling.