Conveyor belt systems are essential in industries ranging from manufacturing and logistics to mining and packaging. These systems depend on a variety of components to function efficiently, and one of the most crucial parts is the conveyor belt rollers. These rollers ensure smooth belt movement, proper tension, and optimal load support. In this article, we'll explore the different types of conveyor belt rollers, including conveyor belt drive rollers, idler rollers for belt conveyors, и conveyor belt guide rollers, as well as their importance in the overall operation of a conveyor system.

The Role of Conveyor Belt Rollers

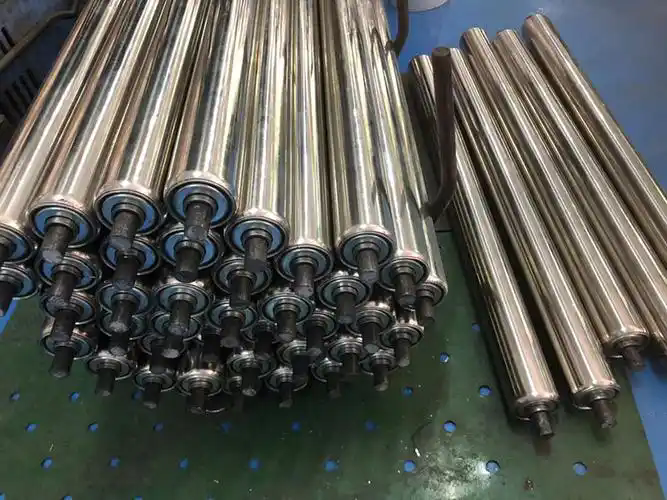

Before diving into the specifics of different types of rollers, it's important to understand the general role of conveyor belt rollers. These rollers are designed to support and guide the conveyor belt, keeping it aligned and ensuring it moves smoothly across the system. They provide friction, support, and resistance to wear and tear. Without reliable rollers, the entire conveyor system could malfunction, leading to downtime, costly repairs, and even safety hazards.

Types of Conveyor Belt Rollers

1. Conveyor Belt Drive Rollers

Belt conveyor drive rollers are the key components that provide the necessary force to move the conveyor belt. They are typically powered by motors and are positioned at the end or middle of a conveyor system. These rollers are responsible for pulling the conveyor belt and enabling it to carry goods from one point to another. Drive rollers are often heavier-duty than other types of rollers because they need to withstand significant mechanical forces.

Table 1: Drive Roller Specifications

| Feature | Specification |

|---|---|

| Material | Steel, PVC, Aluminum |

| Diameter | 50mm - 200mm |

| Power Source | Electric Motor |

| Application | Heavy-duty, High-load |

| Lifespan | 5 - 10 years |

2. Idler Rollers for Belt Conveyors

Idler rollers are another important part of any conveyor system. These rollers support the conveyor belt without providing any driving force. They are primarily responsible for maintaining the belt's alignment and tension. Idler rollers are typically positioned along the length of the conveyor, particularly in areas where the belt needs extra support, such as the return path or the loading zone.

There are several types of idler rollers:

- Return idlers: These support the conveyor belt as it returns to its starting point after unloading material.

- Impact idlers: Placed in areas where heavy loads are transferred, these idlers absorb the shock and prevent the belt from being damaged.

- Troughing idlers: These rollers are arranged at an angle to help contain the material on the belt, particularly for loose or bulk materials.

Table 2: Idler Roller Types

| Idler Type | Function |

|---|---|

| Return Idler | Supports belt return path |

| Impact Idler | Absorbs shock during load transfer |

| Troughing Idler | Contains materials on the belt |

| Training Idler | Keeps the belt aligned |

| Flat Idler | Supports flat conveyor belt sections |

3. Conveyor Belt Guide Rollers

Conveyor belt guide rollers are designed to ensure that the conveyor belt stays aligned and does not deviate from its intended path. These rollers are often used in the middle or at the edges of the conveyor belt system. Guide rollers play a critical role in maintaining the system’s efficiency by preventing the belt from slipping off track, which could lead to jams, wear, or even system failure.

Why Conveyor Belt Rollers Are Essential for Your Conveyor System

The performance of your conveyor system is heavily dependent on the quality and functionality of its rollers. Here are a few reasons why conveyor belt rollers are crucial for smooth operation:

- Enhanced Efficiency: Properly functioning rollers reduce friction, preventing the conveyor belt from excessive wear and tear, thus increasing system longevity.

- Improved Load Handling: Rollers, especially drive rollers, ensure that the belt can carry heavy loads without slipping or breaking.

- Better Alignment: Guide rollers help keep the conveyor belt properly aligned, preventing system malfunctions.

- Reduced Downtime: The longer the rollers last, the less likely your conveyor system will experience breakdowns, leading to improved uptime and productivity.

Conveyor Belt Rollers for Sale

If you’re looking to purchase conveyor belt rollers, you’ll find a wide variety of options available. The market offers different roller types tailored to various applications, from light-duty rollers for smaller systems to heavy-duty rollers for large-scale industrial operations. Whether you need idler rollers или drive rollers, it's essential to choose a high-quality supplier to ensure your conveyor system functions optimally.

One reputable company to consider is Kenaier Conveying Machinery Manufacturing Co., Ltd. Kenaier is a leading conveyor belt rollers manufacturer known for providing high-quality rollers designed for a wide range of industries. They offer a diverse selection of rollers, including idler rollers, drive rollers, и guide rollers, tailored to meet the unique demands of their clients.

Kenaier’s products are known for their durability, performance, and cost-effectiveness. Whether you need rollers for a belt-driven conveyor или return rollers, Kenaier can provide you with high-quality, reliable products to ensure your system runs smoothly.

Conveyor Belt Rollers Suppliers Near Me

When searching for conveyor belt rollers suppliers near you, Kenaier Conveying Machinery Manufacturing Co., Ltd. can often meet your needs. They offer global delivery and have a reputation for quick turnaround times and excellent customer service. Whether you're based in Asia, Europe, or North America, Kenaier’s network of distributors and partners can ensure that your rollers are delivered promptly, minimizing downtime for your operations.

You can also visit Kenaier’s website or reach out to their customer service team to inquire about specific product availability or pricing.

How to Choose the Right Conveyor Belt Rollers

Choosing the right conveyor belt rollers involves considering a few important factors:

- Material: Rollers are typically made from steel, PVC, or aluminum. Steel is used for heavy-duty applications, while PVC and aluminum may be used for lighter loads.

- Load Capacity: Ensure that the rollers are designed to handle the specific weight and volume of materials you’re transporting.

- Durability: Choose rollers that are resistant to corrosion, wear, and impact to ensure long-lasting performance.

- Size: Make sure the roller diameter and width match your conveyor system's specifications.

By working with experienced suppliers like Kenaier, you can ensure that you’re selecting the most appropriate rollers for your system.

Заключение

Conveyor belt rollers play an essential role in the smooth operation of conveyor systems. From drive rollers к idler rollers и guide rollers, each type is designed to serve a specific function, ensuring the conveyor belt moves efficiently and without issue. High-quality rollers not only improve system performance but also reduce maintenance costs and downtime.

When purchasing conveyor belt rollers, consider reputable manufacturers like Kenaier Conveying Machinery Manufacturing Co., Ltd. for reliable, durable products that meet your needs. Whether you're looking for rollers for conveyor belt systems in industrial settings or specialized products like belt-driven conveyor rollers, Kenaier is your trusted source for superior conveyor components.